Producers rarely view water as an agent that accelerates the deterioration of their infrastructure. However, irrigation water can carry microorganisms, sediments, and organic compounds that form biofilms inside gutters, drip systems, and pipes.

The real cost of not disinfecting irrigation water

This biofilm causes blockages, loss of irrigation uniformity, and promotes biological corrosion processes that shorten the lifespan of your systems. Installing an agricultural water disinfection system isn’t just a sanitary measure: it’s an investment in the durability of your gutters and pipes.

What is Pure Hypochlorous Acid (PHA) and why is it ideal for agriculture?

PHA (pure hypochlorous acid) is a broad-spectrum disinfectant that can be generated on-site. Its key advantages for agricultural applications are:

- High efficacy against biofilm and pathogens (bacteria, fungi, algae, etc.), preventing plant diseases.

- Improves root health.

- Environmental disinfection in seedbeds.

- There is no corrosion on materials when applied with the appropriate parameters, compared to aggressive chemicals that can degrade plastics and metals.

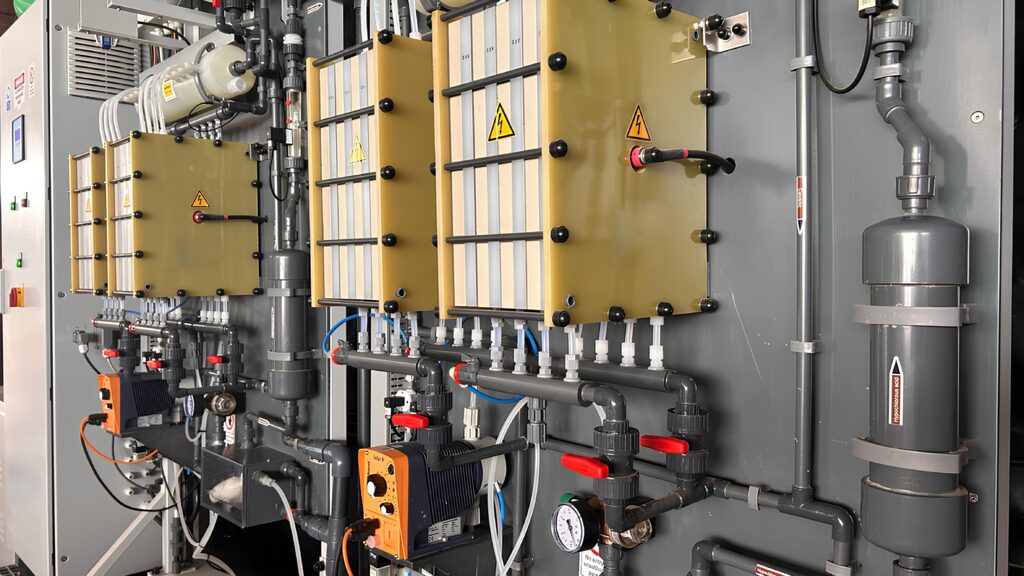

- Continuous and controlled generation, allowing 24/7 treatment in recirculating systems.

- Compatible with organic crops.

For these reasons, PHA-based systems are especially suitable for protecting gutters, pipes, and drip lines without subjecting them to treatments that weaken the material.

How PHA prevents the degradation of gutters and irrigation pipes

- Biofilm prevention: PHA prevents the formation and expansion of biofilm, which traps particles and causes clogging in drippers and nozzles.

- Less microbial fouling: By keeping internal surfaces clean, friction and localized corrosion are reduced.

- Stable flow and uniformity: Pipes and drippers free of obstructions maintain irrigation uniformity, avoiding water stress and production variability.

- Reduction in physical interventions: Less mechanical cleaning, aggressive flushing, and premature replacement of pipe sections or gutters.

- In arid climates, where a cooling pad & fan system is used, it extends the life of wet pads.

Quick Comparison: PHA vs. Other Disinfection Solutions

Before deciding which technology to implement, it’s important to compare Pure Hypochlorous Acid (PHA) with other common solutions for disinfecting irrigation water. Each method has advantages and limitations, and its effectiveness depends on both the water quality and the needs of each agricultural facility. Below, we present a quick comparison to understand why PHA is positioned as one of the safest and most sustainable alternatives for protecting gutters, pipes, and drip irrigation systems.

- PHA: effectiveness against biofilm, in situ generation, continuous control, lower impact on materials if dosed correctly and compatible with beneficial microorganism treatments.

- Commercial chlorine/hypochlorite: Effective, but can generate chlorinated byproducts, causing toxicity in the crop. It is also corrosive to some plastics and seals.

- UV: Excellent as a pretreatment, but does not remove biofilm adhering to surfaces or work in open circuits with sediment. If the downstream pipe is dirty or infected, the UV-treated water becomes infected again. Requires solid-free, clarified filtered water for good UV transmittance.

- Peroxides: Although recommended as an oxidant, their greatest benefit is oxygenation. At recommended doses, their oxidizing power is limited. At high doses, they can detach layers of biofilm, clogging drippers. Biofilm regenerates after 15 days.

For installations with recirculation, external networks, and exposed gutters, the PHA offers an ideal balance between efficiency and infrastructure compatibility.

Where is it especially advisable to install a PHA system?

Installing a PHA disinfection system is especially recommended in greenhouses that recirculate drainage, as the risk of pathogen and biofilm buildup is higher in these types of installations. It is also very useful in high-density crops, such as strawberries, cherry tomatoes, or peppers, where irrigation uniformity makes the difference between a profitable crop and a problematic one.

It is also an ideal solution for farms with a history of dripper blockages or frequent pipe replacements. By keeping pipes clean, PHA helps minimize premature replacement of metal or plastic gutters, prolonging the lifespan of the infrastructure and optimizing the initial investment in irrigation systems.

Maintenance, monitoring, and return on investment (ROI)

- Reduced maintenance: With a properly sized PHA system, intensive mechanical cleaning and chemical washes are reduced.

- Remote control and automation: Many systems allow PHA production to be monitored and dosage adjusted based on demand, optimizing consumption and avoiding overdosing.

- Tangible ROI: Fewer pipe purchases, less labor for cleaning, and fewer production downtimes. In most commercial installations, payback is observed in just a few production cycles (depending on the size and water conditions).

Note: The exact dosage and sizing must be determined by a prior analysis of the water and circuit; always request a technical study before installation.

Practical tips for choosing a supplier of pipes and complementary systems

Compatibilidad de materiales: confirma compatibilidad del proveedor de tuberías de riego con tratamientos de PHA (polietileno, PRFV, acero revestido, etc.).

Garantías frente a biofilm: solicita referencias y casos de éxito donde hayan integrado desinfección continua.

Servicio postventa: el proveedor deberá ofrecer calibración, mantenimiento y formación para el equipo de desinfección.

Suministro de repuestos y soporte local: importante en instalaciones en zonas con reposición logística limitada.

Frequently Asked Questions (FAQ)

Does PHA damage plastic dripline materials?

No. When applied at the proper concentrations and times, PHA acts as a disinfectant without attacking common irrigation plastics; always confirm compatibility with the manufacturer.

Is it safe for the plant and the operator?

Yes: PHA is an approved disinfectant for agricultural applications when used according to specifications; additionally, it is generated on-site, avoiding the storage of hazardous substances.

Can it completely avoid pipe replacements?

Not always: disinfection will extend the lifespan and delay the need for replacement, but mechanical and environmental factors also determine the lifespan. Reduce the frequency and magnitude of replacements.

Would you like a free audit of your irrigation system and a quote to integrate disinfection with PHA?

Contact Hydroponic Systems for a personalized technical study and a proposal that includes compatibility with your gutters, pipes, and dripline systems.

Request a no-obligation quote now by clicking here.